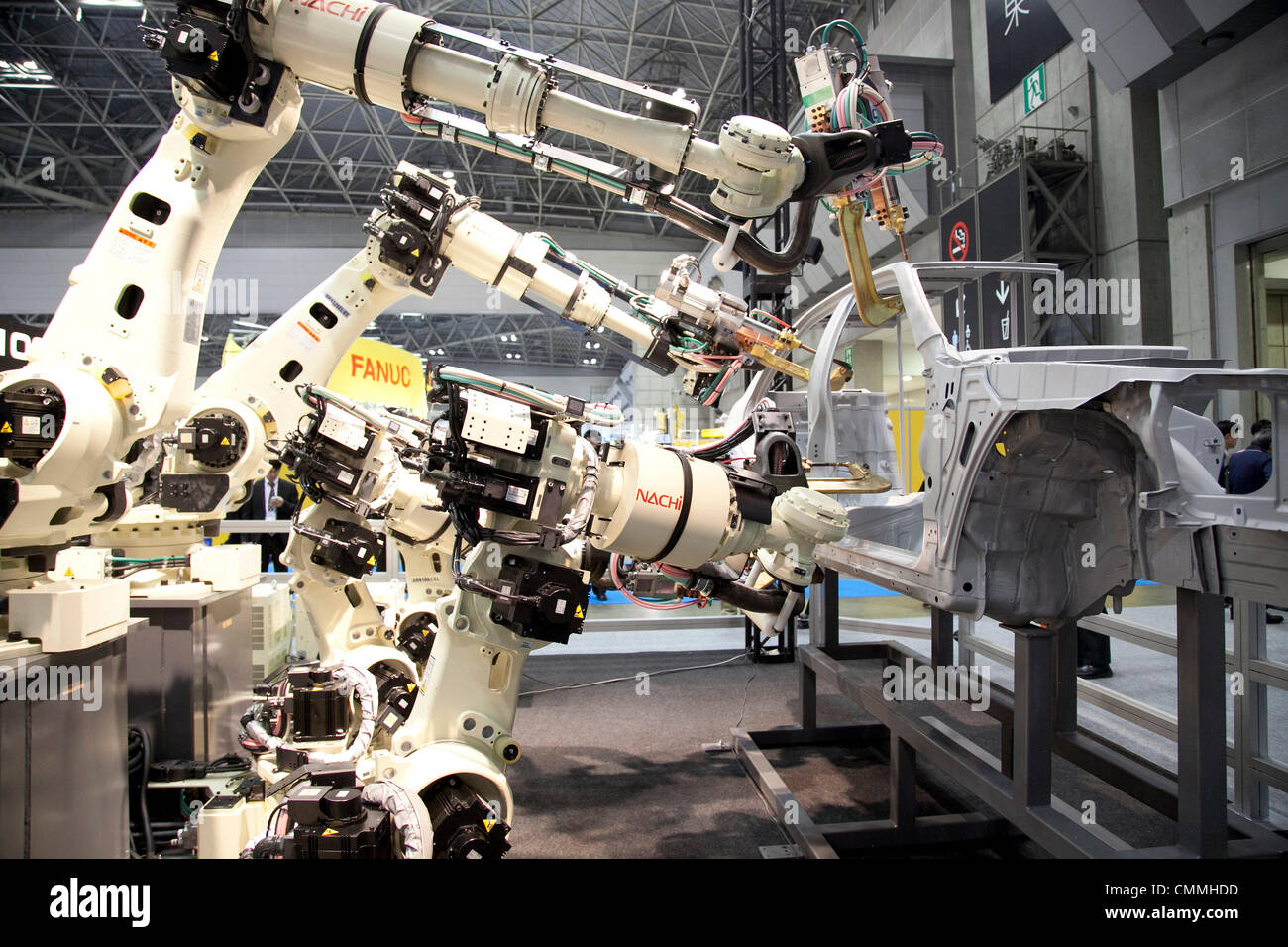

Nachi Aw Robot Manual

Program spotwelding parameters at the touch of a button, intuitive menus provide simple set up of your process. Nachi also accommodates many integrated solutions offered by the various weld timer suppliers.

Allows the user to control all aspects of the spot welding process directly from the robots teach pendant. Complete spot welding system setup, schedule programming, manual welding, weld data results, process monitoring diagnostics, manual gun motion, and much more are standard with Nachi’s spot welding software. Automatically generates programs and complete palletizing routines using basic cell layout data and package measurements. Minimal robot programming is needed to create a palletizing routine that will pick or place literally hundreds of parts.

Off-line Programming Industrial Robots Based in the Information. Input and namely the manual movement, the state reading and the teaching. Then we describe the. Latest from FANUC, ABB, Motoman and Nachi. If this transform is applied to vector w, a wl vector is obtained: (17).

Cod Aw Robot Arm

Standard and custom (“Simple” and “Highly Effective”) palletizing routines can easily be created using the standard palletizing software. “Simple” palletizing software is used to stack parts with standard geometry into even rows and columns.

“Highly Effective” palletizing software is used to create custom pallet layouts with many different offsets and rotation critical placement. Nachi dispensing process functions can adapt to almost any kind of sealant or adhesive, placing the medium accurately and consistently. Using speed proportional output software dispensing control systems function in unison with robot motion. With this solution the dispensing rate is directly proportioned using the robots TCP travel speed. Allows the user to define automatic or proportional dispensing rates, manual dispensing rate, gun number, perform manual operation an purge, refill set points, and operational limits of dispensing equipment.

Hi there, I am new to this Forum. I am having an issue with a test robot we have at our shop. Snap on tools owners manual for toolbox. AW controller and a SF160 robot.It seems that the playback speed of my program is the same as the jog speed I am using.

I have went through every parameter or setting of record and playback that I could find. I have experience with Fanuc but this is really irritating me. Is there a system variable that I may need to change? All i have is the mechanical maintenance manual and the users manual. I do not know of any hidden menus either.

Can somebody help?